The move is complete, APT is 100% operational in all core areas, and the first hoses have already been delivered.

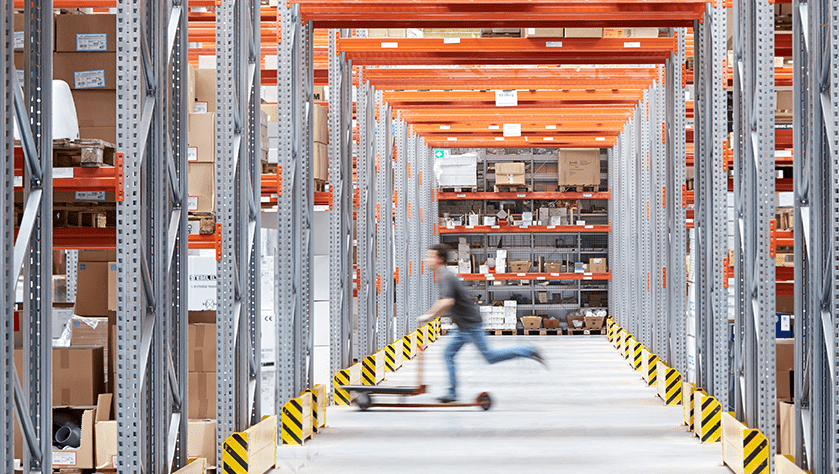

Thanks to the great commitment of all employees, service providers and even colleagues from other Masterflex Group locations, the move went 100% according to plan and smoothly. The new hall in industrial architecture is not only large, bright and modern, but also optimally adapted to APT’s work and process flows.

In the next weeks already, the capacities in the production of shrink tubes (by 30%) and in the extrusion area (by 10% up to 20%) will be expanded. In addition, APT now has climate-controlled and enclosed areas in PTFE production, resulting in a further reduction in the risk of contamination and optimized process quality.

The changeover to a new ERP system has also been 100% successful. Data transfer, inventory and stocktaking have already been completed via the company’s new “control center”. In the future, this will mean an even better data basis and manufacturing processes that can be mapped optimally.

In short: more quality with shorter delivery times.

Managing Director Martin Brück: “We are highly motivated to continue our sustainable growth together with our customers.”