ETFE

Raw material information

ETFE (Ethylene-Tetrafluorethylene) is a partly fluorinated copolymer. Compared to PTFE, ETFE is slightly harder and has a reduced density.

Properties

- Temperature of continuous use ranges from – 50 °C (-58°F) to + 160 °C (+320°F)

- Good chemical stability

- Good mechanical properties

- Very good stability to high-energy rays

- Very smooth and easy to clean anti-adhesive surfaces

- High pressure resistance at room temperature

- Weldable

- Nonflammable (UL 94: V0 classification)

- Low permeability

- Sterilizable and autoclavable

Products

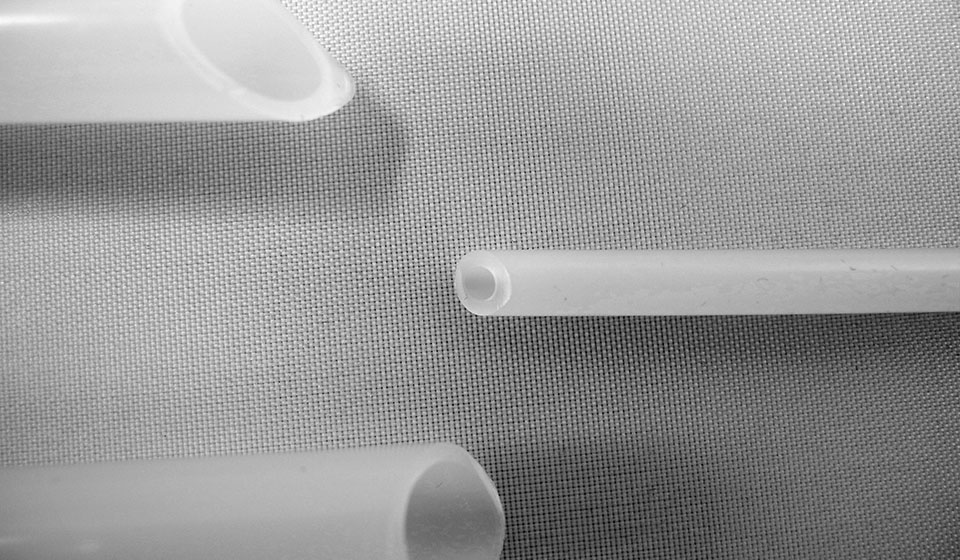

APT produces ETFE tubes from a minimum inner diameter of 0,3mm (0.010”) to a maximum outer diameter of 100 mm (4.000”) and PVDF rods to a maximum diameter of 4,00 mm (0.160”) ETFE is a “made to order” product and we generally do not keep stock of ETFE tubing.

Depending on customer’s request, ETFE tubes can be shipped in coils, on spools or supplied in straight length up to 6 m (18ft.).

Application areas

On basis of these excellent characteristics, ETFE tubes can be used for several applications in the industrial sector:

- Chemical plant construction

- Equipment engineering

- Laboratory techniques and process engineering

- Oil and Gas industry

- Automotive, aerial and spatial engineering

- Medical engineering