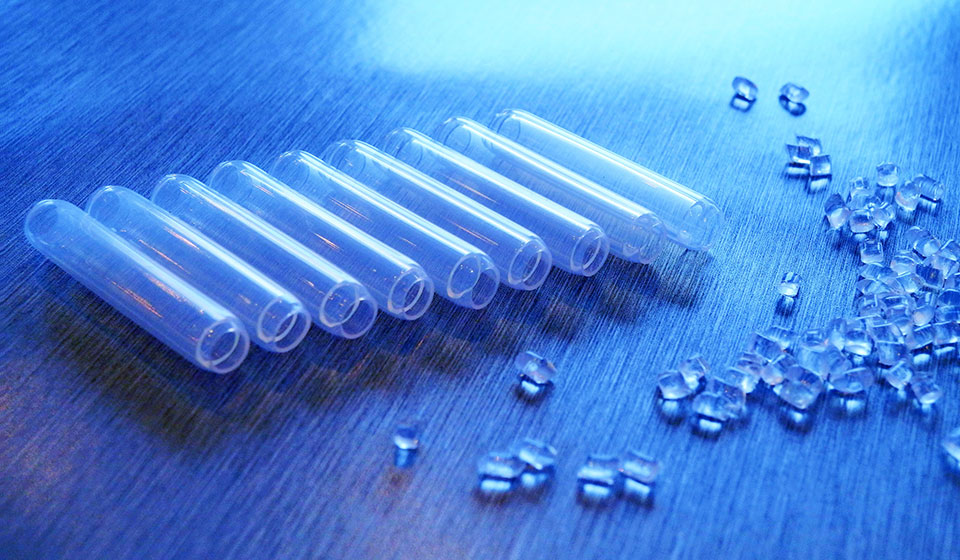

PTFE-FEP dual heat shrink tubes

Raw material information

Our dual-wall heat shrink tubes are manufactured from two layers of different polymers combined with one another. The outer layer is composed of pure PTFE and the inner layer of high-molecular FEP.

During the shrinking process, the outer PTFE layer shrinks at a temperature of about 330 °C (approx. 626° F), whereas the FEP inner layer becomes a semifluid masse. After cooling, a complete dense coating of heat shrink and object is obtained.

Properties

The perfect connection of both layers prevents the inside from falling out, even when being cut to short pieces.

After shrinkage, our dual-wall heat shrink tubes can withstand temperatures from – 200 °C to + 210 °C (- 328 °F to + 410 °F). The sealing after shrinkage is waterproof and withstands aggressive chemicals as well as high and low temperatures.

Products

- 20 different standard dimensions suitable for objects with a diameter from 0,00 mm to 25,00 mm

- Two different wallthicknesses

- Delivered in standard lengths of 1,22 m, other lengths on request

Application areas

Our PTFE-FEP dual heat shrink tubes are mainly used for the production of aerial and moisture-proof cable connections

Remarks

- Standard delivery lengths: 1,22 m (4 ft.)

- Standard color: natural transparent

- Other colors and dimensions on request

- Shrinking temperature: 330 °C +/- 10 °C (626 °F)