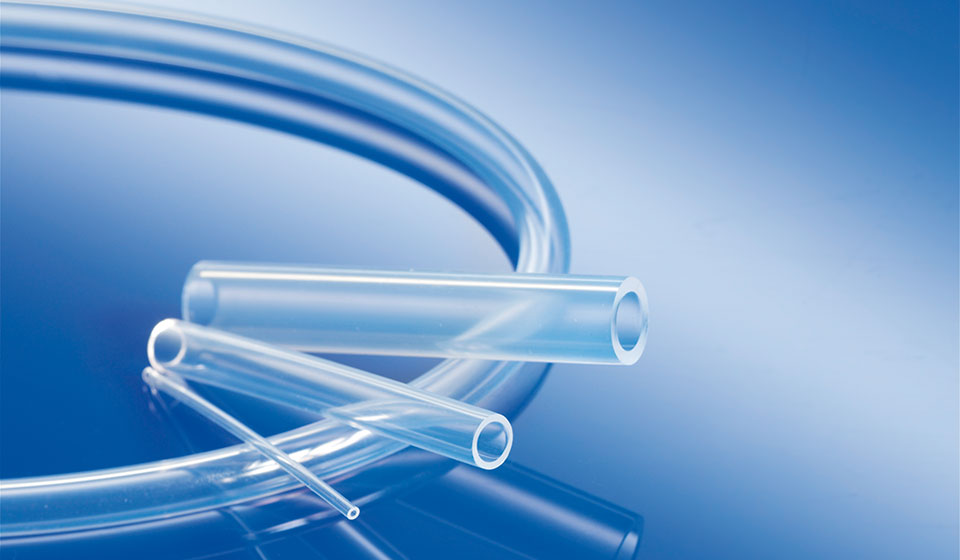

STANDARD-PFA

Raw material information

PFA (Perfluoralkoxy) is a copolymer of TFE (Tetrafluoroethylene) with a side chain modification of PPVE (Perfluopropylvinylether).

Chemically PFA is very closely related to the classic PTFE (Polytetrafluoroethylene). Having a lower melt viscosity PFA can be processed on standard melt extrusion equipment whereas PTFE is a sinter material.

Properties

- temperature os continuous use ranges from – 200 °C to +260 °C

- very high chemical stability

- Transparent to translucent (depending on the wall thickness)

- Very low surface energy and friction coefficient

- Very smooth and easy to clean with anti-adhesive surfaces

- Electrically insulating

- Can be welded

- Inflammable (UL 94: V0 classification)

- Low permeability

- PFA can be sterilized and is autoclavable

- Special grades Compliant to FDA and USP class VI

Products

APT produces PFA tubes from a minimum inner diameter of 0,10 mm to a maximum of 110 mm.

In addition to a wide range of standard dimensions, which we keep in stock, we almost produce every possible required dimension in metric or inch sizes. On request, our PFA tubes can also be colored according to the RAL-color system.

Depending on customer’s request or application, our PFA tubes are packaged in defined ring lengths, wrapped on spools or cut-off length.

Using state of the art extrusion and control equipment we are able to manufacture single on multi-layer PFA tubes in very close tolerances.

Application areas

Based on its unique characteristics characteristics, PFA tubes can be used for several applications in the industrial laboratory and medical sector:

- Chemical plant construction

- Equipment engineering

- Laboratory techniques and process engineering

- Food and bevarage industry

- Paint engineering

- Automotive, aerial and spatial engineering

- Medical engineering

- Domestic appliances

- Electrical engineering