FEP-standard

Raw material information

FEP (Fluorinated ethylene propylene) is a fully fluorinated co-polymer of HFP (Hexafluoropropylene) and TFE (Tetrafluoroethylene) with a glaze point of 260 °C (+500 °F).

FEP upper temperature of continuous use is + 205 °C (+ 401 °F), and its chemical stability remains the same compared to the PFA.

Properties

- temperature of continuous use ranges from – 200 °C (- 328 °F) to + 205 °C (+ 401 °F)

- Universal chemical stability

- Highly transparency

- Very low surface energy and friction coefficient

- Very smooth and easy to clean anti-adhesive surfaces

- Very good insulation properties (electrical)

- Weldable

- Inflammable (UL 94: V0 classification)

- Low permeability

- Sterilizable and autoclavable

- Compliant with FDA and USP class VI

Products

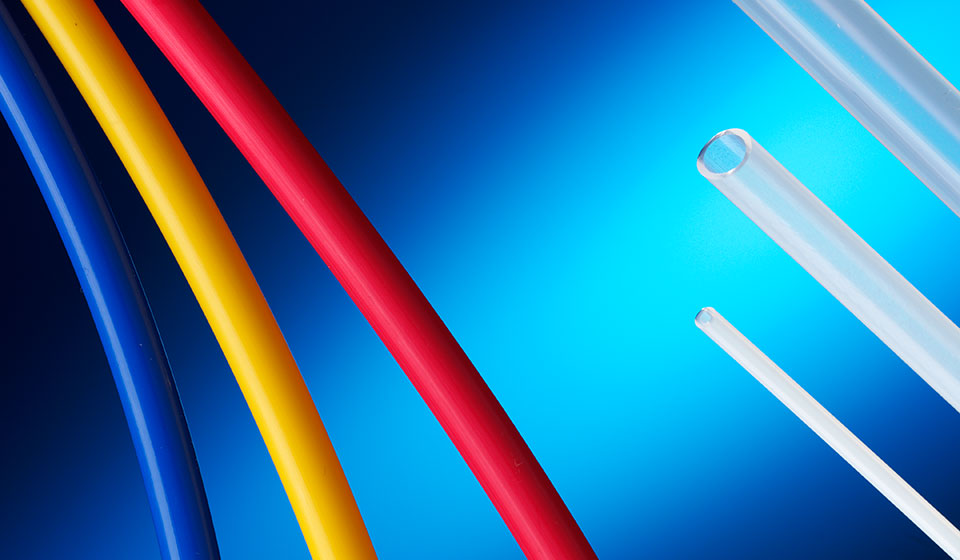

Our product range on FEP tubing covers diameters between 0,10 mm and 110 mm with almost any wallthickness. Customized production runs in metric and inch sizes can be realized with short lead times and even for smaller quantities.

With regard to standard dimensions we carry a large stock of the common sizes mostly in natural colour and in standard length of 50 or 100 m coils. Coloured FEP tubes are made to order according to the RAL colour code.

On request we use continuous x-ray measurement to ensure the quality of our products at any point or fully automated visual inspection.

Multi-layer constructions, welding rods and profiles can be manufactured on request.

Application areas

On basis of those excellent characteristics, FEP-tubes are being used for several applications in industry such as:

- Oil and Gas

- Equipment engineering

- Laboratory techniques and process engineering

- Food and beverage industry

- Printing technology

- Automated Painting technology

- Automotive, aerial and spatial techniques

- Medical engineering

- Domestic appliance

- Electrical engineering