With a view to the war in Ukraine, the corona-related lockdowns in China and the ongoing inflationary pressure on raw material and logistics costs, we find ourselves in times of particular economic uncertainty.

APT, the fluoropolymer specialist within the Masterflex Group, has nevertheless achieved the (almost) impossible: a strong first quarter and double-digit organic growth in a challenging market environment.

How was this achieved? Managing Director Martin Brück: “Well, by investing massively in our core competencies.”

Capacities in the extrusion sector were increased by around one fifth. In addition, the production capacity of shrink tubes was doubled by adding an additional shift.

New employees were hired in sales and production. In the shrink tubing department, working hours were changed to a two-shift system. A three-shift system is being planned due to very high demand.

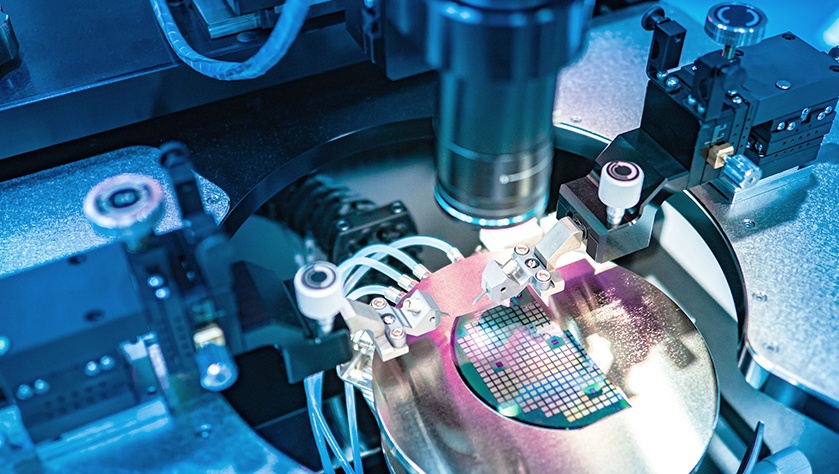

Furthermore, the quality control of the products was further expanded by additional state-of-the-art inline X-ray measuring equipment and a close network was established with all raw material suppliers in order to remain constantly able to deliver despite all the upheavals.

Brück: “We have made the (almost) impossible possible and will continue our planned investments and measures undeterred this year in order to be able to supply our customers and business partners in the best possible way.”

Continue to accompany us on our successful path and follow our regular business updates.